Glen Mhor Log Book 29th June 1939

Our deep dive into the operation of Glen Mhor distillery continues to enthral with each page of the logbook. 1939 is shaping up to be a bountiful year in terms of insight and information and this latest entry from 29th June provides another first.

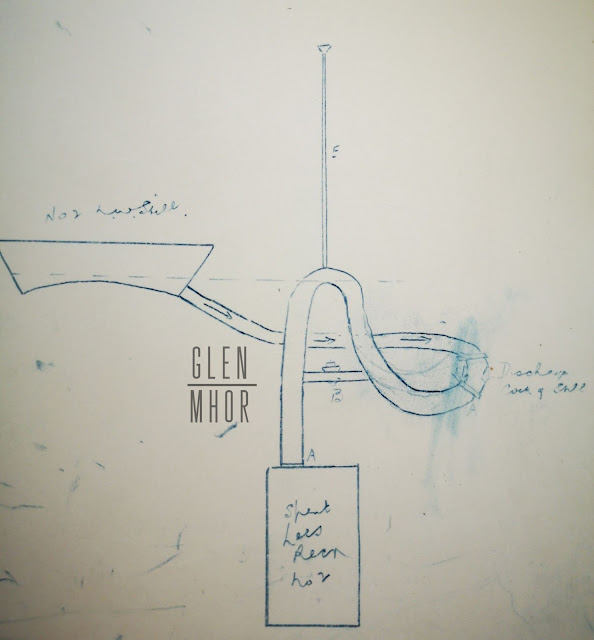

We've seen previous entries that have referred to a sketch or additional material of some form. Sadly, these have never been included in the logbook itself, possibly due to the counterfoil system. However, in this particular entry, we have a botched attempt at sketch which has been scored out. Thankfully, the exciseman for Glen Mhor (Gilbert W. Peterkin), picked up his pen and tried again on a new page.

Regulars will recall we have a new distillery manager at Glen Mhor, which I believe was James Ritchie. His reign started with an early request to ascertain the state of the original Low Wines No.1 Still in January 1938. We don't know the outcome of that request (other than it was approved), however this entry today, suggests that this original Low Wine Still was never brought back into production fully. Instead, the plan looks to be to effectively scavenge parts from its set-up for its larger replacement.

As this logbook takes us into the 1960s, we can say with some confidence that unless the remaining pages say otherwise, the original Low Wine Still was never returned to production. If it did, then there would be a record and a new indulgence granted by Customs & Excise. The actual entry itself from 1939 reads as:

'Glen Mhor Distillery

Inverness

29th June 1939

Honourable Sirs,

Messrs Mackinlay's Birnie Co of Glen Mhor Distillery, Inverness, have handed me the attached application. For provisional approval to transfer the syphon and air pipe from the discharge of No.1 Low Wines Still (a still seldom in use) to No.2 Low Wines Still.

This transfer would allow sufficient spent lees to remain in the No.2 Still after discharge, in order to ??? the protect soldering. The spent lees would cover about 1" of the crown of the still.

The syphon would be inserted between the flange of the discharge cock and the No.2 Spent Lees Box (as per sketch) and securely riveted hereto.

The syphon consists of a bent pipe with a syphon discharge and an air pipe 4' long with ??? top, firmly jointed to the syphon pipe.

The discharge of pipe No.1 Low Wine Still would be jointed by riveting to the flange of the turning cock, and by soldering to the No.1 Spent Lees Box.

By indulgence E33140/25.4.1906 a syphon pipe with an air pipe was allowed on the discharge of No.1 Low Wine Still.

The trader requests cancellation of the above indulgence and the issue of a new indulgence for the syphon and air pipe on No.2 Low Wine Still.

Your authority is requested to allow the work to proceed.

I am, Honourable Sirs, your obedient servant

Gilbert W. Peterkin, officer.

Glen Mhor Station'

Below is the successful sketch attempt, and fortunately, the Exciseman has had the good foresight to include a guide to the drawing, saving us from having to decipher it, nearly 84 years later:

I'm delighted to be able to call upon Alan Winchester to provide this thoughts on these logbook entries. His knowledge and expertise really helps bring these pages into perspective and a whole new dimension of appreciation.

¹ This will become clearer in the next logbook entry, where the completed work is recorded and certified as being up to standard.

This Log Book comes from the Highland Archives Centre (HCA/D31/4/1/25) and is watermarked for its protection. As with any images on this website, please ask first before using and always give credit. My thanks to the Centre for their assistance and also to Rose for her brilliant work to enhance my terrible photographs.

Comments

Post a Comment